Our Blogs

How to Choose the Right Cable for Your Project

Choosing the right cable is not as simple as picking the first one you see in a catalog. The wrong cable can result in equipment failure, power loss, safety hazards, or project delays. To avoid these issues, businesses must carefully evaluate the technical requirements, environment, and compliance standards.

Here’s a step-by-step guide from Neskeb to help you select the right cable for your project.

1. Identify the Application

- Power Transmission – Requires high-voltage or medium-voltage cables.

- Automation/Control – Needs control or instrumentation cables.

- Data & Networking – Fiber optic or Ethernet cables are best.

The first step is always understanding where and how the cable will be used.

2. Check Voltage & Current Ratings

Each cable has a specific voltage rating (e.g., 110V, 220V, 11kV) and current capacity. Using an underrated cable may cause overheating, while an overrated cable increases unnecessary costs.

✅ Always match the cable rating to your equipment’s requirements.

3. Consider Environmental Conditions

Cables often face harsh conditions. Ask yourself:

- Will the cable be installed indoors or outdoors?

- Will it be exposed to chemicals, heat, or moisture?

- Does it need to be fire-resistant or UV-protected?

For example:

- Outdoor power lines → UV and weather-resistant cables.

- Factories with high heat → Heat-resistant cables.

- Oil plants → Chemical-resistant sheathing.

4. Ensure Compliance with Standards

Using certified cables is not just about quality—it’s also about legal compliance. Look for:

- IEC, ISO, BIS certifications.

- Fire and safety approvals.

- Environmental certifications.

At Neskeb, every cable undergoes rigorous testing and certification before reaching clients.

5. Factor in Cost vs. Longevity

It’s tempting to choose cheaper cables, but they often need frequent replacements. A higher-quality cable may cost more upfront but saves significantly in the long run by reducing downtime, energy loss, and maintenance costs.

Conclusion

The right cable ensures safety, efficiency, and smooth operations. By considering application, rating, environment, compliance, and cost, you can make an informed decision.

At Neskeb, we don’t just manufacture cables—we help our clients choose the right ones for their unique needs.

Copper vs. Aluminum Cables – Which is Better?

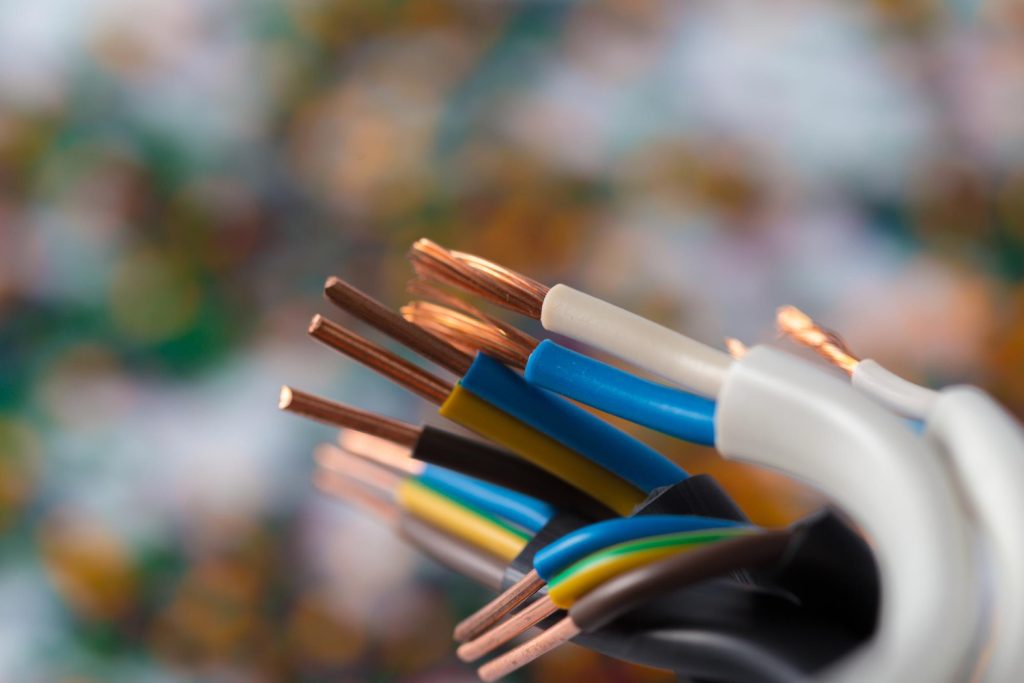

When it comes to choosing cables, one of the most debated questions is: Copper or Aluminum? Both metals are widely used in cable manufacturing, and each has unique strengths. To make the right choice, industries must consider performance, cost, and application requirements.

At Neskeb, we specialize in both copper and aluminum cables. Let’s compare them side by side.

1. Copper Cables

Copper has been the gold standard for electrical conductors for decades.

- High Conductivity – Carries more current with less energy loss.

- Durability – Resistant to corrosion and wear.

- Flexibility – Can handle frequent bending without breaking.

- Reliability – Long lifespan with stable performance.

✅ Best for: Data centers, critical industries, and applications requiring maximum reliability.

2. Aluminum Cables

Aluminum cables are lightweight and cost-effective, making them popular for certain applications.

- Lightweight – Easier to transport and install.

- Lower Cost – More affordable compared to copper.

- Good Conductivity – Though not as high as copper, aluminum works well for large-scale power transmission.

✅ Best for: Power grids, overhead lines, and long-distance electricity transmission.

3. Comparison Table

| Feature | Copper Cables | Aluminum Cables |

|---|---|---|

| Conductivity | Very High | Moderate |

| Weight | Heavier | Lightweight |

| Cost | Expensive | Affordable |

| Flexibility | Excellent | Moderate |

| Lifespan | Very Long | Good |

4. Which One Should You Choose?

- For critical industries (hospitals, IT, aviation): Copper is the safest choice.

- For large-scale power transmission where weight and cost matter: Aluminum is ideal.

- Hybrid Approach: Some industries use a mix of copper and aluminum to balance performance and cost.

Conclusion

There’s no one-size-fits-all answer. Both copper and aluminum cables have their advantages. The right choice depends on your project’s budget, application, and safety requirements.

At Neskeb, we manufacture both copper and aluminum cables, ensuring the best match for your needs.

Types of Industrial Cables and Their Applications

Cables may seem like simple wires, but in reality, they are the foundation of modern infrastructure. From transmitting electricity to enabling communication networks, every industry relies on specialized cables. Choosing the wrong cable can lead to inefficiency, safety hazards, or even equipment failure.

At Neskeb, we manufacture a wide range of industrial cables designed for different applications. Let’s explore the main types of industrial cables and where they are used.

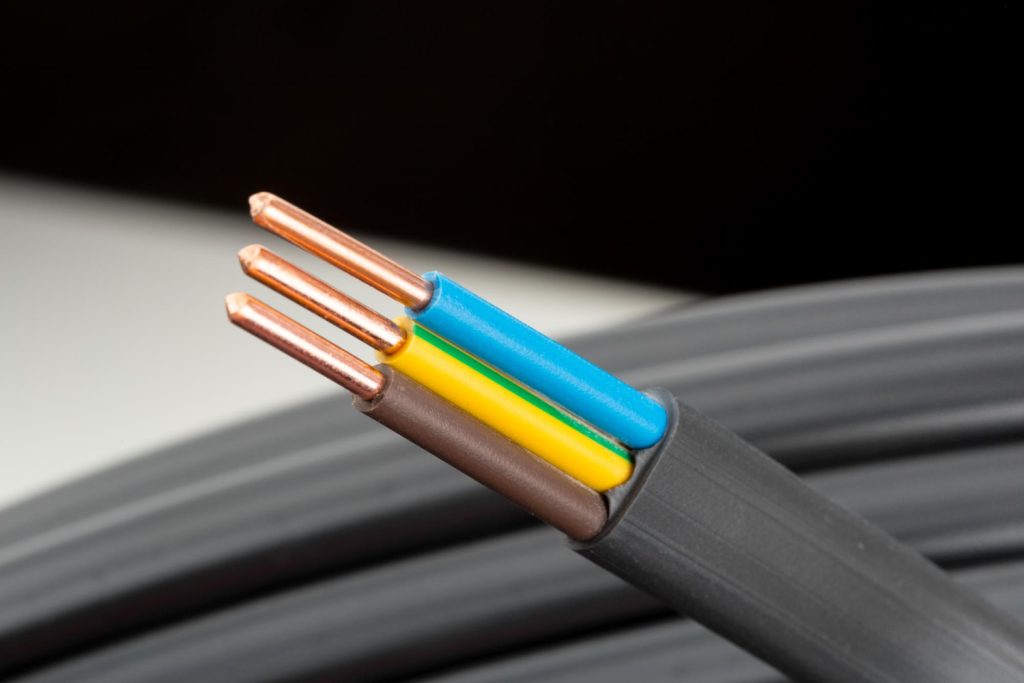

1. Power Cables

Power cables are the most common type, designed to transmit electricity from one point to another. They are found in homes, factories, commercial complexes, and utility networks.

- Low-Voltage Power Cables – Used in residential and office spaces.

- Medium-Voltage Power Cables – Common in industrial plants and local grids.

- High-Voltage Power Cables – Suitable for power stations and long-distance transmission.

✅ Application: Power distribution, electrical panels, renewable energy projects.

2. Control Cables

Control cables are used to regulate and manage equipment. They are typically multi-core cables that transmit signals to operate machines or automation systems.

- Flexible Design – Can handle frequent bending.

- Durable Insulation – Protects against oil, heat, and mechanical stress.

- Signal Accuracy – Ensures precise communication between control systems.

✅ Application: Robotics, assembly lines, conveyor belts, and automation systems.

3. Instrumentation Cables

Instrumentation cables carry low-voltage signals for monitoring and controlling sensitive equipment.

- Shielded Designs – Reduce electrical interference.

- Fire-Resistant Options – Enhance safety in critical environments.

✅ Application: Petrochemical plants, refineries, power plants, and laboratories.

4. Data & Networking Cables

In today’s digital era, data cables are as important as power cables.

- Coaxial Cables – Used in CCTV, broadcasting, and communication systems.

- Ethernet Cables (Cat5, Cat6, Cat7) – Enable internet and networking.

- Fiber Optic Cables – Ultra-fast data transmission across long distances.

✅ Application: IT infrastructure, telecom, offices, smart cities.

5. Specialty Cables

Specialty cables are designed for specific environments where standard cables cannot perform.

- Fire-Resistant Cables – Maintain power supply during fire.

- Heat-Resistant Cables – Withstand extreme temperatures.

- Marine & Offshore Cables – Resistant to water, oil, and salt.

✅ Application: Aerospace, defense, oil rigs, chemical industries.

Conclusion

Every project requires a different type of cable. Using the right cable not only ensures safety but also enhances efficiency and reliability. At Neskeb, we manufacture a complete range of power, control, data, and specialty cables that meet global standards.

The Importance of High-Quality Cables in Modern Industries

In today’s fast-paced world, industries depend heavily on a reliable supply of power, data, and control systems. At the heart of all these systems lies one essential component—cables. They may look simple, but cables play a critical role in ensuring safety, efficiency, and uninterrupted operations. Unfortunately, many businesses compromise on cable quality to save costs, only to face bigger losses later due to breakdowns, energy losses, or even accidents.

At Neskeb, we believe that cables are not just products—they are lifelines of industries. Let’s dive into why investing in high-quality cables is not a luxury, but a necessity for every sector.

1. Safety Comes First

Electrical safety is a top concern across industries. Faulty or substandard cables are one of the leading causes of short circuits and fire hazards. Inferior insulation can easily melt under high current, exposing wires and putting entire facilities at risk.

High-quality cables, on the other hand, are:

- Manufactured with flame-retardant materials.

- Tested to withstand high temperatures and harsh environments.

- Designed with superior insulation and sheathing to prevent leakage.

By choosing the right cables, businesses can prevent costly accidents, safeguard their workforce, and comply with safety regulations.

2. Enhanced Performance and Reliability

A cable is not just a conductor of electricity—it’s a medium of efficiency. Low-grade conductors can result in higher resistance, leading to energy losses, overheating, and inefficiency.

Premium cables ensure:

- Better conductivity using high-purity copper or aluminum.

- Lower energy loss, which translates to cost savings.

- Consistent performance even under heavy loads and long operating hours.

This reliability is especially crucial for industries like IT, manufacturing, and healthcare, where downtime is not an option.

3. Durability and Long-Term Value

High-quality cables are designed to last. From chemical plants to offshore drilling rigs, cables must withstand tough conditions such as moisture, heat, abrasion, or bending.

Durable cables provide:

- Resistance to weathering and corrosion.

- Tough sheathing that protects against cuts and wear.

- Flexibility to support frequent movement without breaking.

While cheap cables may need frequent replacements, investing in durable cables ensures long-term savings and less operational disruption.

4. Meeting Industry Standards and Certifications

Every industry has strict standards for cables. For example:

- ISO, IEC, and BIS certifications ensure compliance with global quality.

- Fire safety standards are critical in construction and public infrastructure.

- Specialized certifications are needed for aerospace, defense, and oil & gas sectors.

High-quality cables from manufacturers like Neskeb are tested and certified to meet or exceed these standards, ensuring businesses remain compliant and future-proof.

5. Supporting Sustainability Goals

Modern industries are not only judged by performance but also by their commitment to sustainability. Poor-quality cables consume more energy and degrade faster, leading to waste and environmental harm.

By investing in efficient, eco-friendly cables:

- Companies can reduce their carbon footprint.

- Improve energy efficiency across operations.

- Support global initiatives for a greener future.

At Neskeb, we integrate sustainability into our manufacturing by using recyclable materials and energy-efficient processes.

6. Cost vs. Value – Why Quality Pays Off

Many businesses fall into the trap of buying cheaper cables to cut upfront costs. However, the hidden costs of downtime, maintenance, and energy losses are far greater.

Think of it as an investment rather than an expense:

- Cheap cable = low upfront cost, high replacement/repair cost.

- Premium cable = higher upfront cost, long-lasting, fewer replacements.

Over time, quality cables always prove more cost-effective.

Conclusion

High-quality cables are the unsung heroes of modern industries. They protect lives, power businesses, ensure uninterrupted performance, and support sustainability. Whether you’re running a manufacturing plant, a data center, or a construction project, investing in quality cables today means building a safer and more efficient tomorrow.

At Neskeb, we are committed to delivering cables that not only meet but exceed global quality standards. Our products are designed for industries that can’t afford to compromise.